What is a Drop Forged Double Coupler?

A drop forged double coupler is a crucial component in the scaffolding industry, providing strong and secure connections between scaffold tubes. It ensures stability and safety in temporary structures used in construction, maintenance, and industrial projects. This article will explore the definition, manufacturing process, advantages, and applications of drop forged double couplers.

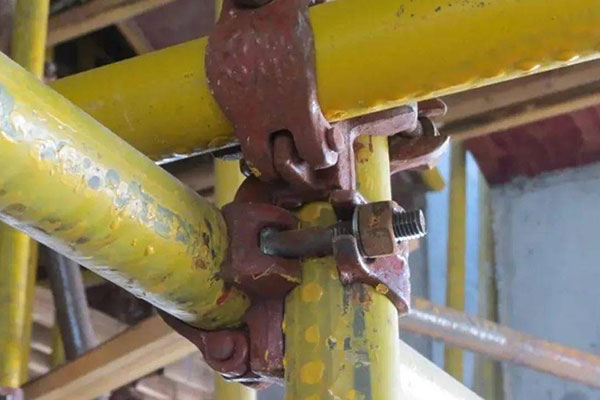

Understanding Drop Forged Double Couplers

A double coupler, also known as a right-angle coupler, is designed to join two scaffold tubes at a 90-degree angle. The term “drop forged” refers to the manufacturing process, which involves shaping the metal under high pressure to create a robust and durable component. These couplers are widely used in scaffolding systems to provide strength and stability in heavy-duty applications.

Manufacturing Process of Drop Forged Double Couplers

The drop forging process involves:

- Heating the Metal – Steel or other durable metal is heated to a malleable state.

- Forging the Shape – The heated metal is pressed into a die under high pressure, ensuring a dense and strong structure.

- Trimming and Finishing – Excess material is removed, and the surface is treated for corrosion resistance.

- Quality Control – Each coupler is tested for durability, load-bearing capacity, and compliance with industry standards.

Advantages of Drop Forged Double Couplers

- High Strength & Durability – The forging process enhances structural integrity, making these couplers capable of handling heavy loads.

- Corrosion Resistance – Most drop forged couplers are galvanized or treated to prevent rust and increase lifespan.

- Secure Grip – Designed for a firm connection, ensuring scaffolding stability.

- Compliance with Safety Standards – These couplers meet international safety regulations, making them reliable for construction use.

Applications of Drop Forged Double Couplers

- Construction Sites – Essential for scaffolding structures in building projects.

- Industrial Maintenance – Used in refineries, power plants, and factories.

- Shipbuilding & Offshore Projects – Provides secure scaffolding for marine and oil industries.

- Infrastructure Development – Applied in bridges, roads, and railway construction projects.

Conclusion

A drop forged double coupler is an indispensable part of scaffolding systems, ensuring safety and stability in various construction and industrial applications. With superior strength, durability, and compliance with safety standards, these couplers provide a reliable solution for secure scaffolding connections. When choosing scaffolding components, selecting high-quality drop forged double couplers can significantly enhance the safety and efficiency of your project.

Shelter is a professional scaffolding couplers supplier. If you are looking for these products for your project, you can contact us directly for more information.