How to Choose the Right Scaffolding Coupler?

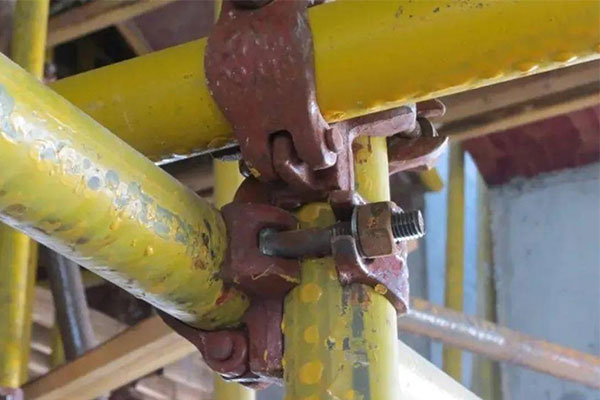

When it comes to scaffolding systems, couplers play a crucial role in ensuring safety, stability, and efficiency on construction sites. Choosing the right scaffolding coupler is vital for both compliance and productivity. Here’s an in-depth guide to help you make the best choice for your specific needs.

Understanding Scaffolding Couplers

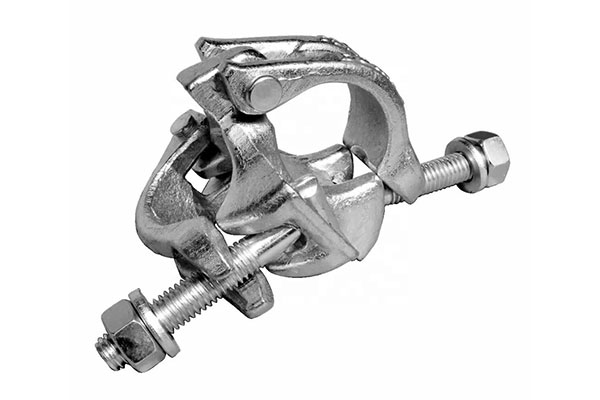

Scaffolding couplers are fittings used to connect scaffolding tubes or pipes securely. They are available in various types, each designed for specific applications and load requirements. The primary types of scaffolding couplers include:

- Right-Angle Couplers: Used to connect two tubes at a 90-degree angle, ensuring structural integrity in frame construction.

- Swivel Couplers: Allow tubes to connect at various angles, offering flexibility for diagonal bracing or irregular structures.

- Sleeve Couplers: Join two tubes end-to-end for extending lengths.

- Putlog Couplers: Attach transoms or putlogs to ledgers or uprights, supporting working platforms.

Key Factors to Consider When Choosing Scaffolding Couplers

1. Material Quality

High-quality materials ensure durability and safety. Most scaffolding couplers are made from steel or forged steel due to their strength. Opt for couplers that meet international standards such as BS1139 or EN74.

2. Load Capacity

Understand the load requirements of your project. Couplers must be capable of bearing the intended weight without risk of failure. Always consult manufacturer specifications to ensure compliance.

3. Compatibility

Ensure the couplers are compatible with your scaffolding system. Mixing incompatible components can compromise stability and safety.

4. Corrosion Resistance

Construction sites often expose scaffolding to harsh weather. Couplers with galvanized or anti-corrosion coatings enhance longevity and reduce maintenance costs.

5. Ease of Use

Consider couplers that are easy to install and dismantle, especially for projects requiring frequent adjustments. This saves time and labor costs.

6. Certification and Compliance

Choose couplers that meet safety standards and certifications in your region. For instance:

- ISO 9001 for quality management.

- ANSI/ASSE scaffolding standards in the U.S.

- BS EN 74 for Europe.

Why Quality Matters

Inferior scaffolding couplers can lead to accidents, legal liabilities, and project delays. Investing in high-quality couplers ensures:

- Worker safety

- Compliance with regulations

- Long-term cost savings

Conclusion

Choosing the right scaffolding coupler is critical for the success and safety of your construction project. By considering factors such as material quality, load capacity, compatibility, and certification, you can ensure a reliable and efficient scaffolding system.

For high-quality scaffolding couplers and expert guidance, explore our wide range of products designed to meet international standards. Contact us today to find the perfect solution for your needs!